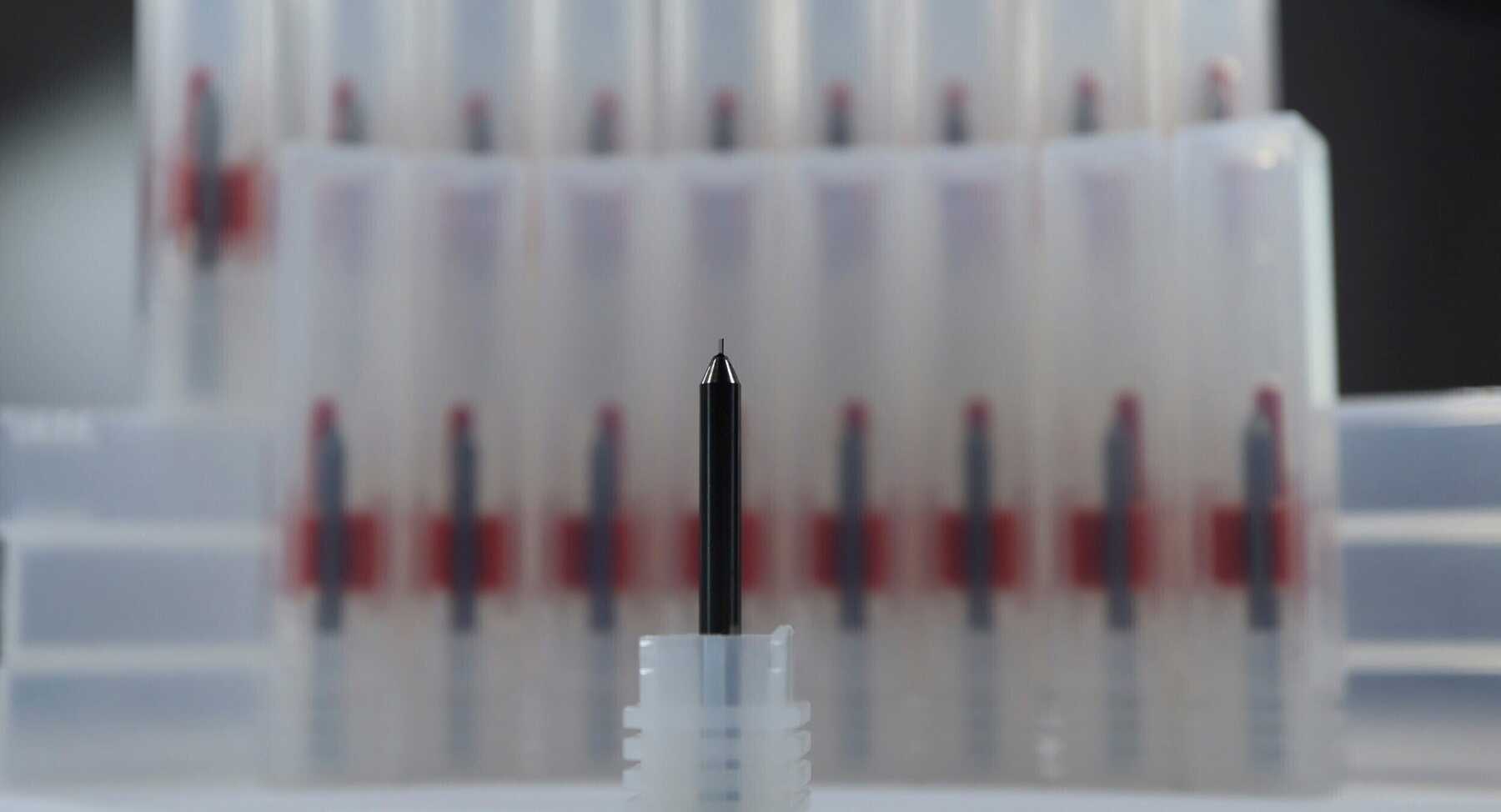

Micro Cutters with extreme lifetime

DD Group developed a range of high quality cylindrical milling tools for cutting intraocular implants and micro structures.

Benefits

- Tool life 10,000 – 15,000 IOL Lenses

- Dramatic reduction of machine downtime (at least 150 times less) in replacing conventional cutters

- Highest accuracy

- Superior surface finish, less polishing required

- Perfectly balanced

Cutting parameters

Milling at normal temperature:

- The feed (mm/min) should not exceed the spindle speed (RPM) divided by 1000 (example: RPM 40,000 then feed maximum 40mm/min)

Milling in frozen material:

- The feed (mm/min) should not exceed the spindle speed (RPM) divided by 300 (example: RPM 40,000 then speed maximum 130mm/min).

Recommendations

Our IOL diamond milling tools can be used on PMMA and foldable materials, fixed with wax, vacuum or ice. Only use on machines with air bearings and with a spindle which is perfectly balanced.

Not recommended for drilling. Theoretically it is possible, but because of possible problems with chip-congestion the tool can break. So therefore always ramp down in material at an angle.

Availability

- From Ø0.35mm cutting diameter and larger

- Working Length 2x cutting diameter

- Shank dimension standard Ø3.0mm

Questions?

At Dutch Diamond Group I am the product specialist for micro cutting tools. Feel free to contact me by phone or E-mail.